The production of medical equipment requires high precision and accuracy to ensure the safety of patients. Plastic injection molding has been increasingly adopted by medical device manufacturers to produce medical parts with high quality and consistency. In this article, we will discuss the importance of medical parts molding and the benefits it provides to the healthcare industry.

What is Medical Parts Molding?

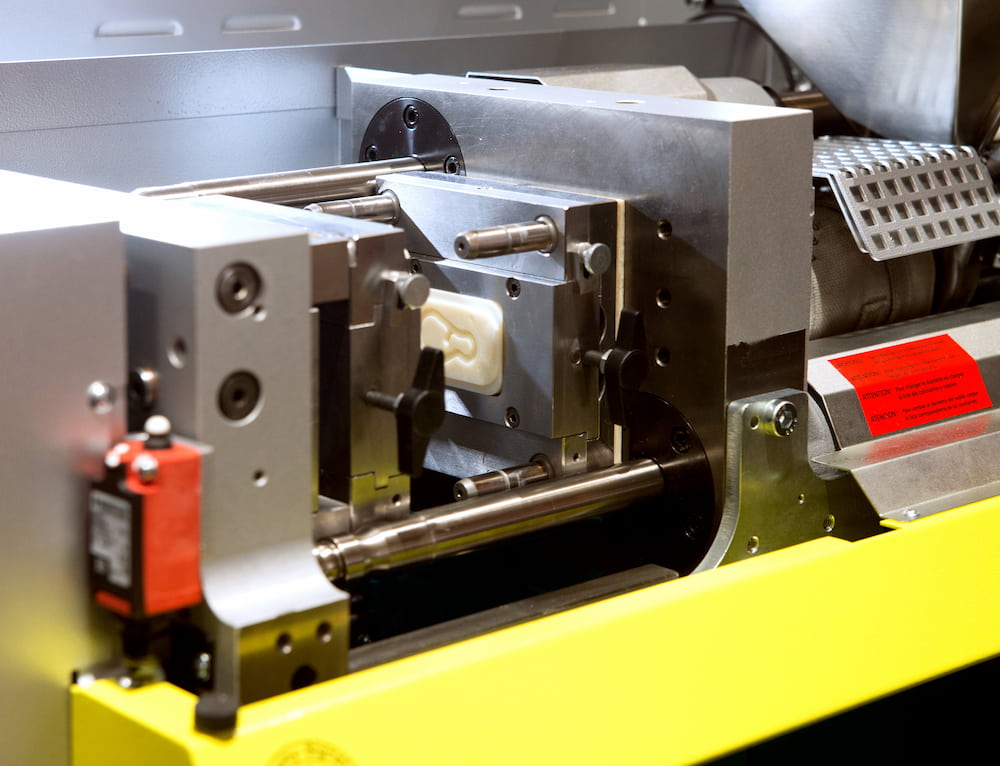

Medical parts molding is a manufacturing process that uses plastic injection molding to produce medical parts for the healthcare industry. This process involves melting plastic resins and injecting them into a mold cavity with high pressure. The molten plastic is then cooled and solidified to form a finished medical component. The process is highly automated, which allows for high-volume production of consistent quality parts.

Why is Medical Parts Molding Important?

Medical parts molding has become increasingly important in the healthcare industry due to the high demand for quality medical equipment. Medical devices need to meet strict regulations and standards to ensure their safety and efficacy. Medical parts molding offers several benefits that make it an ideal solution for producing high-quality medical devices.

1. Consistency: Medical devices need to perform consistently to ensure the safety of patients. Plastic injection molding provides a high level of consistency, which is essential for producing medical parts that meet the required specifications.

2. High-Quality Parts: Medical parts molding offers a high level of accuracy and precision, ensuring that the medical components produced are of superior quality.

3. Flexibility: Medical parts molding offers excellent design flexibility, enabling it to produce complex medical parts with intricate geometries.

4. Cost-Effective: Medical parts molding is a cost-effective manufacturing method, allowing medical device manufacturers to produce medical parts at a lower price point.

Benefits of Medical Parts Molding

Medical parts molding has several benefits that make it an ideal solution for producing medical components. Some of these benefits include:

1. Reduced Production Time: Medical parts molding is a highly automated process, which makes it possible to produce medical parts at a high volume in a relatively short period.

2. Reduced Waste: Medical parts molding produces little to no waste since the process is highly controlled and precise, ensuring that the material is used efficiently.

3. Enhanced Productivity: Medical parts molding is a highly efficient process, which enhances productivity, ensuring that medical components can be produced in large quantities.

4. Scalability: Medical parts molding is a scalable manufacturing process, meaning that it can easily adjust to changes in demand without compromising the quality of the medical components produced.

Conclusion

The healthcare industry demands high-quality medical equipment that meets strict regulations and standards. Medical parts molding offers several benefits that make it an ideal solution for producing medical components that meet these requirements. The process is highly automated, consistent, cost-effective, and offers design flexibility, ensuring that medical manufacturers can produce high-quality medical equipment that meets the needs of patients. If you require medical parts molding services, contact a reliable medical parts molding provider today.